Volume 24 - Autumn 2007

How I Do It: Tool Sharpening

by Kathy Abbott

I sharpen both my spokeshave and paring knife in the same manner; that is by using a honing guide, diamond whetstones, a ceramic sharpening stone and a strop.

I should point out that the spokeshave holder must be adapted from being a wood working tool to one that is suitable for paring leather. The depth of the mouth (opening) should be made wider by using a metal file, rubbed against the lower edge of the opening. (Ed - see Skin Deep, vol. 16) This is done to stop the leather parings from becoming packed within the opening whilst paring. The base of the spokeshave holder should also be backed off (as described below) so that it is absolutely flat and smooth. Before using the spokeshave blade, you must round off the corners, again using a metal file. This is done to stop the blade from catching the leather at the corners whilst paring.

Firstly, I back off the blade of either the spokeshave or paring knife. This should be done before using either blade for the very first time and also each time the blade becomes very blunt. Backing off is done by rubbing the back of the blade (the side without the angle) up and down a blue, coarse diamond whetstone, which has been moistened with a small amount of water. The blade must be held absolutely flat on the whetstone. I keep doing this until the back of the blade is evenly ground (an even, dull sheen will appear on the back of the blade) and there is no trace of a burr on this side. Backing off is important, as blades are rarely completely flat when they come from the manufacturers. If the back of the blade is not ground absolutely flat, it will not cut evenly.

Note: It is important that you stand whilst sharpening a blade. By applying the whole of your body weight in this way you will sharpen the blade more quickly and evenly.

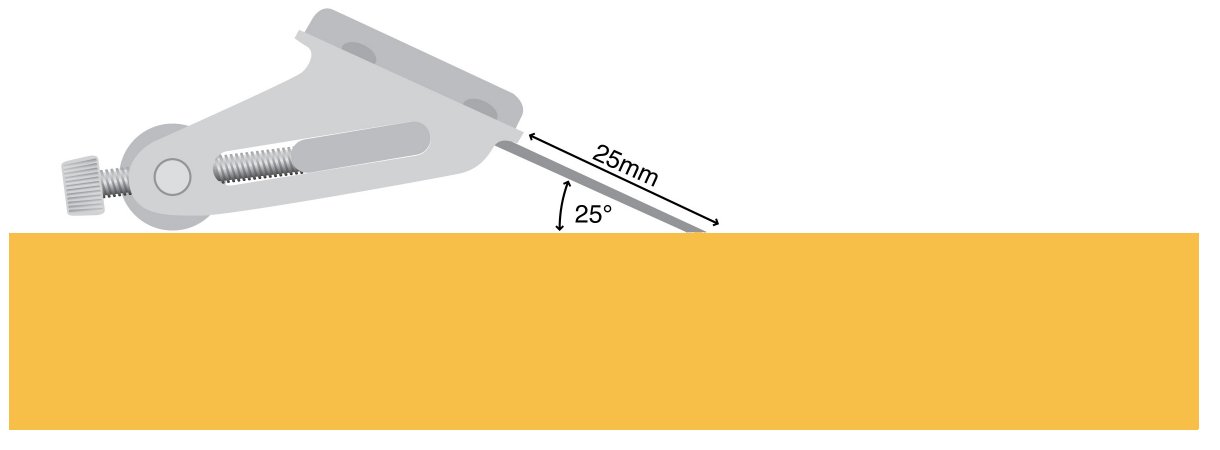

When sharpening a spokeshave blade, after the blade has been backed off, I place it with the angled side facing downwards, into a honing guide. The one I prefer to use is a Stanley 81-050 honing guide, which is an angled guide on two small rollers. The flat side of the blade must protrude from the edge of the honing guide by exactly 25mm to give a sharpening angle of 25º (this is my preferred angle, though a deeper angle is also permissible and is favoured by some binders. If a longer bevel is required, the blade should protrude from the honing guide by 30mm). It is essential that the blade is set accurately to this measurement so that I can ensure that the blade will be sharpened to the exact same angle in the future.

When I am satisfied that I have an exact 25mm protrusion, I firmly tighten the screws in order to ensure that the blade does not move whilst sharpening. I then place the blade (within the honing guide) with the angle facing downwards onto the coarse whetstone, again, moistened with water. I place my fingers on the flat panel of the honing guide and rub the blade up and down the length of the stone using a firm downward pressure. It is important not to slip off either end of the stone, as this can result in the chipping of the blade. I continue to do this until the angle is evenly ground.

I then take a red, fine diamond whetstone and without removing the blade from the honing guide, I repeat the process. The angle should now start looking evenly shiny. I then turn the blade over, still within the honing guide and, making sure that the back of the blade is absolutely flat on the stone, I back the blade off again to remove any burr caused from sharpening the angled side.

Still without removing the blade from the honing guide, I repeat the process on a fine ceramic stone (no water necessary). The blade will now be very shiny on both sides and should feel very sharp.

Note: Diamond whetstones and ceramic stones should be used for sharpening as they remain absolutely flat, unlike oil or sand stones, which become dipped with time.

I finish off the blade by removing it from the honing guide and then by lightly stropping it on a leather strop, which has been previously with a small amount of jeweller's rouge.

I place the blade back into the spokeshave holder with the angled side of the blade facing downwards. I adjust the screws of the spokeshave until approx. 0.5mm of the blade is protruding from the base. The blade needs to be stropped occasionally when paring a skin, to freshen up the blade (I don't remove the blade from the handle to do this). I would expect to sharpen the blade to the degree described above after paring about two skins (depending on their size).

I use the exact same process for sharpening my paring knife, which is a modified hacksaw blade, 23mm x 180mm in size. The blade however, cannot be gripped in the honing guide as it is - the metal is too thin - so I wrap a piece of leather around the length of the blade to thicken it. I sharpen the paring knife also to a 25º angle.

Note: A standard paring knife cannot be sharpened within this honing guide.

The diamond whetstones discussed in this article are DMT Bench Whetstones, coarse and fine 150mm x 50mm. The ceramic stone is a fine Spyderco Ceramic Bench Stone 200mm x 50mm. Both types of whetstone are available from Axminster Tools (in the UK).

Kathy Abbott served a four-year apprenticeship in bookbinding and then gained an HND from the London College of Printing and a BA from Roehampton University. She is currently self-employed as a bookbinder and book conservator working part-time as bindery manager at Bernard Quaritch Ltd. She teaches at the City Literary Institute and West Dean College and conducts many workshops across the UK. She has been exhibiting with Tomorrow's Past since its formation in 2003