Volume 29 - Spring 2010

Single Leaf Binding

by Nick Cowlishaw

Emil Lumbeck, a German Bookbinder, introduced the double fan binding process in the 1930's.

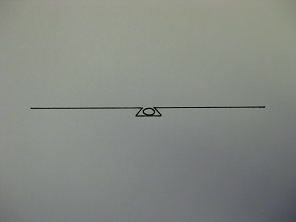

Each leaf is secured to the other with a fine line of adhesive applied when the single leaf text block is in a fanned position.

To increase strength, thin cords can be recessed diagonally across the spine after the adhesive application in a process known as band driving.

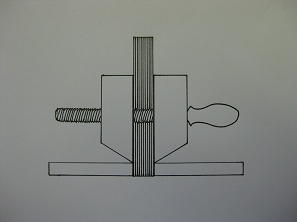

The Lumbeck technique can be carried out with the use of a finishing or small lay press.

A protective waste sheet of clean paper, followed by a thin flexible card, is placed on each side of the book. The book is knocked square on the spine and head and placed in the press with a centimetre of the spine proud of the cheeks. This can easily be achieved by inverting the press and positioning it on two one centimetre thick pressing boards.

If the foredge of the book protrudes beyond the bottom of the press it will have to be supported on blocks when it is turned over to the upright position.

|

|

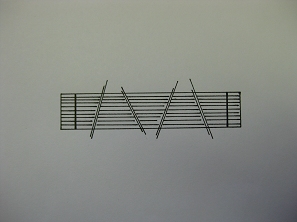

It is at this stage that the cord recesses can be made. Four diagonal cuts are made across the spine using a fine saw held at a 45O angle to create an inverted flowerpot like cavity, a two-ply sewing cord should be of adequate thickness to fill the cavity. Two fine saw cuts at head and tail can also be made to accommodate a thin sewing thread simulating the kettle stitch on a sewn book.

|

|

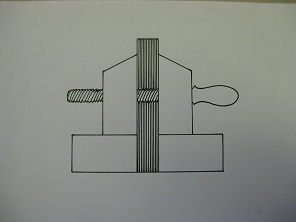

After sawing, the book is raised in the press until between two and three centimetres of the foredge are gripped by the cheeks.

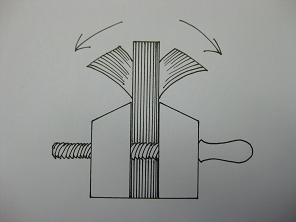

The book is pushed over until it touches the side of the press first one way and then the other and reversible PVA applied in each fanned position.

After the adhesive applications the book is lowered back down into the press until one centimetre protrudes and the cords and threads are pushed into the saw cuts.

It is possible to round the spines of these books, prior to inserting the cords and threads, by removing the wet adhesive from the saw cuts with a knife and allowing the spine to partially dry before removing the book from the press and rounding the spine on the bench in the usual way. After rounding, the book is returned to the press, the saw cuts re-glued and the cords and threads inserted.

When completely dry the book is removed from the press and the thin card and waste sheet removed. The sewing thread is cut off flush with the spine and the cords are cut or frayed out to become part of the binding structure.

Nick Cowlishaw started an apprenticeship in bookbinding at the age of fifteen. After many years hand bookbinding for various companies, he took up lecturing in the craft. Nick taught at the London College of Printing. Today he teaches advanced classes in Craft Bookbinding at Morley College, London. Nick and his wife Charlotte formed their own bookbinding business, Cowlishaw Bookbinding in 1996.

Nick's informative DVD, 'Rebacking a Cloth Binding', published by the Society of Bookbinders is available to purchase from our web site.