Volume 32 - Autumn 2011

One Year On

a word from our Managing Director, Roger Barlee

We are now just over a year on from the start of the move from Currie, and can finally say that we have caught up on everything. The first 3-4 months of the move are a bit of a blur especially as the final stages of leaving Kinauld Leather Works went anything but smoothly.

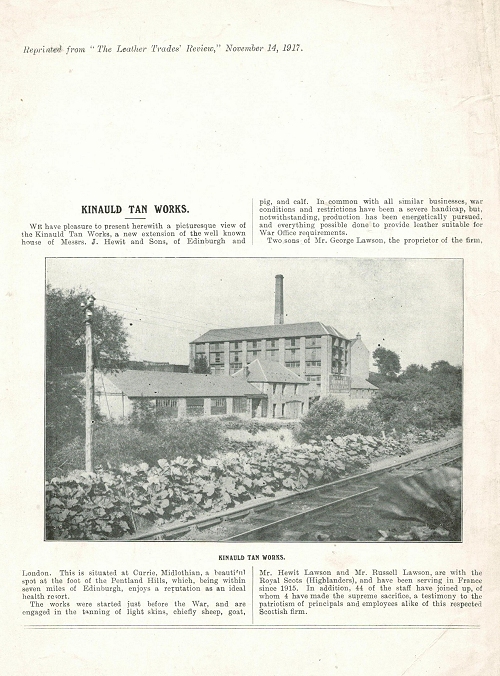

Kinauld Leather Works was obtained by George Lawson, my Great Grandfather, in 1913 and purchased a few years after the Great War. Below is an advert from the 1917 Leather Trades Review and a photograph showing the building, as it was when we took it over. Bar replacing the windows on the west side of the building in the 1970s very little changed in the 97 years we were there.

The property started its life as a papermill, and there are records showing that Nisbet and MacNiven founded the mill in 1770. Originally this was only what we later used as the office block, but over the next 100 years the premises that many people knew and loved developed. The papermill closed in 1882 and lay empty for most of the next 30 years. The water wheel in the mill was used for power, until too much water was being taken from the lochs above Balerno and it was de-commissioned in 1950. The main wheel measured 12 feet in length and had a diameter of 18 feet with a drop of 22 feet and at peak output that could produce 36 Horse Power.

Water Wheel Axle

Water Wheel Axle

The building was obtained in order to increase capacity to allow the start of production of pigskins for leathergoods, the main tannery being off the High Street in Edinburgh. At that time Scottish pigskins were used widely for leathergoods as Ayrshire bacon was rind-free, so skins were readily available, and around 400 pigskins were tanned each week for the next 70 years until fashions changed. Originally the building was used solely as an additional tanyard and drying area with pits along the riverbank outside the office block and main building. These were eventually enclosed around 1950 when my father joined the Company. Initially most of the chemicals and skins were delivered by rail, with the tannery having its own siding off the Balerno railway line until the late 1950s. As time went on however more of the building was used for additional finishing, and in the picture below you see the back finishing shop being used to manufacture "Ideal" leather Golf Grips. In 1970 the City Tan Works were closed and all production moved to Currie after my father invested in more modern machinery.

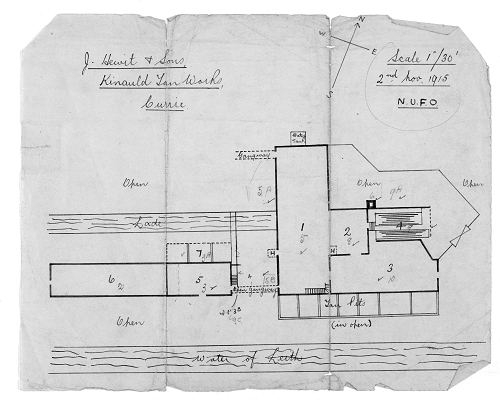

Plan of Kinauld Leather Works 1915

Plan of Kinauld Leather Works 1915

Whilst Currie was a vast improvement on the City Tan Works where everything had to be taken up and down the old closes in Edinburgh, time eventually took its toll on Currie. We were having more and more problems with articulated lorries refusing to come down our steep hill, especially in the winter and the old building was beginning to feel its age. The biggest issue was stopping water getting in when it rained. The main problem being that the roof was an inverted "W", and when the water wheel was being removed in 1950 some bright spark though it a good idea to take out the centre pillar to allow more room. Whilst it certainly helped with the removal of the water wheel, when they came to replacing the pillar they found the building had sunk by nearly a foot! This meant that the water, instead of running off the roof when it rained collected in the middle and despite all our best efforts we just could not stop the water coming in.

Pictures of Kinauld Leather Works from Golf Monthly 1935

Pictures of Kinauld Leather Works from Golf Monthly 1935

In the late 90s it became obvious that the central wooden beam on the fifth floor was beginning to go soft around the edges, and it then became a matter of do we sell up or move since repairing the roof five floors up was never going to happen. For me selling up was never an option as leather tanning was too deeply ingrained in my blood, so we carried on as before waiting for a suitable offer. This eventually came and resulted in the most stressful 7 months of my life. The idea had been, when production stopped in July 2010, that we would be able to get started in some form by November.

What we had not taken into account was that at the new property i Livingston, the water board would be unable to find the water meter. In the end it took them over 4 months! This was necessary in order to upgrade the supply from a 12mm domestic pipe to something more suitable for tannery production. By the time production did finally restart in February 2011, I had appreciably less hair than a year before!

The old site is now completely demolished and is being turned into a nursing home and a few flats.

Nettlehill Road has proved to be so much easier to run being all on one level. With concrete floors rather than wood it has also meant that we can put machines and racking cheek-by-jowl and so we have managed to fit virtually everything we had in Currie into a smaller, but far more sensibly organised building.

Edinburgh Evening News, August 2011

Edinburgh Evening News, August 2011

The new Tannery and Warehouse at Livingston

So to the future. We were in City Tan works for 106 years, Kinauld Tan Works for 97 years,

so on that basis we should we be looking for new premises in around 2099, although I doubt I will still be around!!