Volume 12 - Autumn 2001

Development of Archival Quality Leather

by Roger Barlee BSc, M.R.S.C.

Work was done in the early 1980's by Betty Haines of the then British Leather Manufacturers Research Association into resolving the long-term problem of identifying good quality bookbinding leathers. The need for a standard for archival leather was considered necessary because of the lack of any reliable guide by which a purchaser could be assured of obtaining a new binding leather with good long term stability. This arose because:

- Leather from a specific region could not necessarily be guaranteed to have been made using tannins from that region

- The PIRA test had proved to be unreliable

In addition to this, it was known that the rate of ageing of Bookbinding leathers is increased by urban pollution. The work proved that vegetable tanned leathers re-tanned with aluminium salts had a greatly improved resistance to deterioration, and that chrome/vegetable tanned leathers have greatly reduced durability, especially of the grain. The work resulted in the publication of a British Standard for Archival Bookbinding Leather - BS 7451:1991 - Specification for Archival Bookbinding Leather (see Appendix A). Unfortunately, although of high archival quality, the leather produced was too stretchy to pare easily and was highly water-resistant. This was partly due to the direction of the research (homing in on the archival properties), and also because of the lack of knowledge at the time regarding semi-aluminium leather production. As a result the general reaction of bookbinders was to try the material once and never come back! This therefore meant that concerned bookbinders and archivists were no better off than they had been before the work was carried out in that they were not in a position to tell a good long-lasting leather (pyrogallol tanned) from a non-lightfast leather (catechol tanned).

The work of Betty Haines was followed by two further European Union funded research projects - the STEP and ENVIRONMENT Leather projects. The result of these projects was an artificial ageing regime, along with recommendations that vegetable tanned bookbinding leathers should be manufactured using pyrogallol tannages, (already done at Hewits) and keeping the sulphate content of the leather as low as possible. The artificial ageing system that was recommended involved heating the leather to 120ºC (later 150ºC) and 35% Relative Humidity (RH) for 6 days. The process being carried out 4 times in total. for 24 hours, and then holding the leather in a polluting atmosphere of 20ppm SO2 and 10ppm NO2 at 40ºC and 35% Relative Humidity (RH) for 6 days. The process being carried out 4 times in total.

Craft Project BE-S2-3432 - "Development of Archival Quality Leather" was a pan-European project intending to have a fresh look at the whole archival leather position. The group was made up of tanners, bookbinders and research bodies from the UK, Germany, Italy and Greece, and the major objectives at the start were as follows:

- Evaluation of leathers currently used for bookbinding across Europe.

- To develop a leather quality testing scheme, that defined binders requirements in an objective manner understood by both the tanner and the binder.

- Optimisation of semi-metal tannage, whereby a leather with all the required properties could be produced with a life expectance of twice the normal life of the vegetable tanned leather stored in polluted atmospheres.

- To investigate the applicability of innovative "metal-free" tannery processes to consistently produce archival quality tannages.

During the first year of the project 72 modern bookbinding leathers representing the whole spectrum of European bookbinding and archival quality leather production were studied. The leathers were tested for their physical and chemical properties, and in addition the bookbinders graded the leathers on their feel and handle as well as on how easily they pared and could be used for binding. These 'organoleptic tests' (as they became called) graded the leathers from 0 (completely unsuitable) to 4 (ideal), with an overall result of 3 (or 4) needed for a "pass" - not surprisingly it was ONLY the leathers produced by specialist bookbinding tanners like J. Hewit & Sons Ltd that passed!

As one can imagine, this resulted in a mass of data from which it became apparent that there was correlation between some of the physical tests carried out on the leathers and the organoleptic tests. However the best correlation invariably resulted from new objective tests specifically aimed at mimicking the handling and working of the leather by the bookbinder. During the second year the physical tests were narrowed down to the following:

- Softness: a measure of how soft and elastic the leather felt

- Wettability: new test indicating the absorbency of the leather to paste and glaire

- Mouldability: new test correlating to how easily the leather may be moulded and retain its shape during bookbinding

- Notch Sensitivity Factor: new test to assess how easily a leather could be pared or shaved during bookbinding

In addition to the above, the Resistance to Flexing whilst under strain was measured as an indication to the strength of the leather on the joint. Together these tests resulted in a specification for a craft bookbinding leather (Appendix B). The methods for the 3 new tests can be found in Appendices D-F.

Whilst this work was been carried out, work was also under way into looking at the accelerated ageing of the 72 leathers using an artificial ageing chamber. Initially the leathers were tested using the procedure used from the STEP project, however it became clear that this test produced anomalies compared with known results of leathers over the last few hundred years - both alum tawed leather and vellums failed quite dramatically.

As was stated above, the original ageing process involved periods in the ageing chamber along with repeated periods at a temperature of up to 150ºC, and it soon became apparent that it was the heating of the leathers that was causing the problems. The process was then refined without the heating stages, and leathers of known tannage were tested over increasing periods. The ageing regime that was finally implemented involved holding the leather in a polluted atmosphere containing 25ppm SO2 and 5ppm CO2 at 40ºC and 35% RH for 12 weeks. After the 12 weeks the residual shrinkage temperatures (Ts) were measured in order to look for leathers with either a high residual Ts, or a low drop in Ts. The results in line with known natural ageing - Chrome tanned leathers being the best, followed by alum tawed and vellum, with vegetable tanned leather being the most degraded.

One unusual result was that some purely native processed Nigerian goats did far better than expected, however when Nigerian leather were further processed (shaved, dyed and retanned) they fared similarly to other vegetable tanned leathers. Whilst some work was carried out to try to identify why this was the case, the emphasis of the project then swung back to the earlier work on semi-aluminium tannages, although other combination tannages were also looked into.

The work carried out to date by J. Hewit & Sons Ltd. has been on our Chieftain Goatskin. Using our experience of semi-aluminium leather production over the last 15 years along with some new ideas that came from the research bodies, we were able to produce leathers that met all the conditions fairly early on in our trials. To ensure that the leathers were indeed suitable for bookbinders, we distributed skins widely to regular Chieftain Goat users around the world, and had a very favourable response. As a result we made the decision to move our whole production over to the newly developing leather at the beginning of 2001. If you have been buying Chieftain Goats regularly over the last year you will no doubt have already encountered the new tannage. Unfortunately scaling up of trials to full-scale production has not run perfectly, and the 16-20 week testing turn around from start of production of a batch to results from the ageing trials has not helped matters. That being said we are now very close to achieving not only the full specification from the craft project, but also the much tighter specification of the British Standard as can be seen below.

NEW HEWIT CHIEFTAIN vs. BS STANDARD

| Al content | around 2.8% can be achieved whilst still complying with Craft physical tests. Currently slightly short in bulk production. Best result 2.8%, current average 2.6% |

| pH | PASS - approx. 4.5 |

| Shrinkage Temp | >115 is achievable - currently averaging 114ºC |

| Tear Strength | PASS - averaging around 35N (range 30 - 48N) |

| Flex Test | currently being achieved in approximately 70% of the leathers |

| Surface shrinkage | Not tested |

In the results tables (See Appendix G) we have shown typical results for some of the many different European bookbinding leather types tested in the project. (We have concentrated solely on goatskins since to date we have carried out no development work on semi-aluminium Calfskins). You can see that, in addition to the known good materials, alum and vellum, the only leathers that pass the organoleptic tests, the physical tests and the ageing tests are the semi-aluminium leathers. The results to date for the new Chieftain Goat are extremely encouraging. We feel confident in stating that, on the basis of the work carried out, we are now meeting the 3rd of the Craft Project objectives - that of twice the life expectancy of a normal vegetable tanned bookbinding leather.

Appendix

A - British Standard

for Archival Bookbinding Leather -

BS 7451:1991 - Specification for Archival Bookbinding Leather

|

Chemical

Properties

|

||

| Test | Method | Required Result |

| Aluminium Content (Al2O3) | BS 1309:1974 :15 | Not less than 2.8% |

| pH | BS 1309:1974 : 8 | Not less than 4.0 |

|

Physical

Properties

|

||

| Test | Method | Required Result |

| Shrinkage Temp | BS 3144:1968 : 17 | Not less than 115ºC |

| Tear Strength | BS 3144:1968 : 6 | Not less than 25N |

| Flexural Endurance | BS 5131:4.2 | Not less than 100,000 |

| Surface Shrinkage | Not greater than 2% | |

Appendix B - Craft Project Guidelines for Bookbinding Leather

| Test | Method | Required Result |

| Flexural Endurance | BS 5131:4.2 | Not less than 2,500 |

| Wettability | See Appendix D | Less than 2 minutes |

| Mouldability | See Appendix E | Less than or equal to 75º |

| Notch Sensitivity Factor | See Appendix F | Not less than 2.2 |

| Softness | IUP6 | 6 3.0 - 8.0mm |

Appendix C - Craft Project Recommendations for Bookbinding leathers to be used for archival purposes.

|

After

12 weeks in the artificial ageing chamber the leather should pass the

tests below

|

||

| Test | Method | Required Result |

| Shrinkage Temperature | IUP 16 | Not less than 70ºC, or Reduction less than 20ºC |

| Flexural Endurance | BS 5131:4.2 | Not less than 1,000 |

Appendix D - Wettability Test

1.

Aim - To assess how easily leather uptakes/absorbs water.

1.

Aim - To assess how easily leather uptakes/absorbs water.

2. Apparatus and reagents

- Distilled water

- Pipette or similar device, capable of dispensing a 0.025 ± 0.01cc droplet of water &

- Stop Watch

3. Procedure

- Condition the samples in accordance with IUP 3 for 48 hours before proceeding with the testing

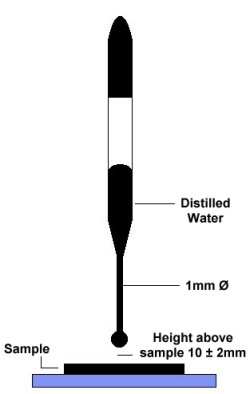

- Place a single droplet (0.025 ± 0.01cc) of distilled water onto the grain or the prepared flesh surface as shown in the figure using a 1mm diameter capillary pipette. (Care must be taken to ensure that the droplet must not disintegrate when placing on the leather.) Distilled Water 1mm Ø Height above Sample sample 10 ± 2mm.

- Measure and record the time taken for the droplet to be completely absorbed by the leather.

4. Results

- Repeat the procedure 4 times to calculate the average absorption time.

Appendix E - Mouldability Test

1. Aim - To assess how well leather may be moulded and retain its shape during bookbinding.

2. Apparatus and reagents

- Cutting Device, capable of cutting the leather samples

- Saturated solution of copper sulphate

- Incubator or conditioning cabinet, capable of maintaining a temperature of 20 ± 2ºC

- 20N weight with a base large enough to completely cover an area 2.5cm x 2.5cm

- Protractor

- Stop Watch

3. Procedure

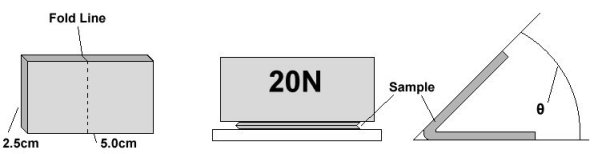

- Cut four rectangular samples 2.5 x 5.00cm (from the official sampling position - IUP2). Fold Line 2.5cm 5.0cm Sample ?

- Condition the samples at 98% RH for 48 hours before proceeding with the test

- Fold the sample in half with the grain surface facing outermost, place on a flat surface and apply the 30N load for 30 seconds

- Remove the load and measure the angle as in indicated in the figure above, 10 seconds after removing the 20N load.

4. Results

- Average the measured values

Appendix F - Notch Sensitivity Test

1.

Aim - To assess how easily leather can be pared or shaved during bookbinding.

1.

Aim - To assess how easily leather can be pared or shaved during bookbinding.

2. Apparatus and reagents

- Cutting Device, capable of cutting the leatherTensometer

- Thickness Gauge

- Vernier Calliper

3. Procedure

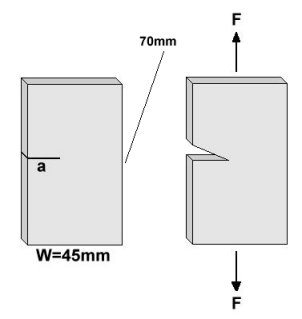

- Cut four rectangular samples 4.50 x 7.00cm (from the official sampling position - IUP2).

- Condition the sample in accordance with IUP 3 for 48 hours prior to testing.

- Cut single edge notches of various length (ranging from 5mm to 35mm in the mid region of specimen as shown in the figure

- Measure and record the length a of the notch using vernier calliper. 70mm

- Determine the thickness t of the samples using official method IUP 4

- Clamp the specimen between the jaws of the tensometer, and extend the samples to breaking at a speed of 100mm per minute.

- Record the maximum tearing force F

4. Results

- Average the thickness reading t

- Calculate and record the notch length as a ratio to the width a/w

- Calculate the force per unit thickness F/t

- Find the natural logarithmic value of force per unit thickness In F/t

- Plot In F/t vs a/w and record the gradient of the slope.

Notch Sensitivity factor = Gradient of Slope

|

Key

to tables below

|

|

Leathers

in Bold are from J. Hewit & Sons Ltd

|

|

n/r

= No result available

|

Appendix G - Results

Subjective tests carried out by bookbinders

Leather

Type

|

Tannage |

Softness |

Paste

Penetration |

Moulding |

Paring |

Overall |

Indian

Goat |

Veg

+ Chrome re-tan |

3 |

2 |

2 |

3 |

2 |

Indian

Goat |

Full

Chrome Tannage |

3 |

1 |

2 |

2 |

2 |

Nigerian

Goat |

Native

+ Veg (UK) |

2 |

4 |

4 |

4 |

3 |

Nigerian

Goat |

Veg (native

tanned) |

4 |

4 |

4 |

4 |

4 |

Indian

Goat |

Chrome

+ Veg |

3 |

1 |

3 |

2 |

2 |

Indian

Goat |

Veg

Chieftain Goat |

3 |

3 |

3 |

2 |

3 |

Indian

Goat |

Archival

- Best Result |

n/r |

n/r |

n/r |

n/r |

|

Indian

Goat |

Archival

- Average to date |

n/r |

n/r |

n/r |

n/r |

|

European

Goat |

Vellum |

n/r |

4 |

3 |

n/r |

4 |

European

Goat |

Alum

Goat |

3 |

3 |

3 |

2 |

3 |

New objective physical tests

Leather

Type |

Tannage |

Softness |

Wettability |

Mouldability |

Notch |

Flex |

Overall |

Indian

Goat |

Veg

+ Chrome re-tan |

Pass |

2 |

2 |

n/r |

Pass |

2/4 |

Indian

Goat |

Full

Chrome Tannage |

Pass |

1 |

2 |

n/r |

Pass |

2/4 |

Nigerian

Goat |

Native

+ Veg (UK) |

Fail |

Pass |

Pass |

Pass |

Pass |

4/5 |

Nigerian

Goat |

Veg (native

tanned) |

Pass |

Pass |

Pass |

Pass |

Pass |

5/5 |

Indian

Goat |

Chrome

+ Veg |

Fail |

Fail |

Fail |

n/r |

Pass |

2/5 |

Indian

Goat |

Veg

Chieftain Goat |

Pass |

Pass |

Pass |

n/r |

Pass |

4/4 |

Indian

Goat |

Archival

- Best Result |

Pass |

Pass |

Pass |

Pass |

Pass |

5/5 |

|

Indian

Goat |

Archival

- Average to date |

Fail |

Pass |

Pass |

Pass |

Pass |

4/5 |

European

Goat |

Vellum |

n/r |

Pass |

n/r |

n/r |

Pass |

2/2 |

European

Goat |

Alum Goat |

Pass |

Pass |

Fail |

n/r |

Pass |

3/4 |

Results of Craft Project ageing trials

Leather

Type |

Tannage |

Initial

pH |

Aged

pH |

Ts |

Aged

Ts |

Flex |

Aged

Flex |

Indian

Goat |

Veg

+ Chrome re-tan |

3.3 |

2.2 |

103 |

80 |

18162 |

8239 |

Indian

Goat |

Full

Chrome Tannage |

3.8 |

2.2 |

115 |

90 |

34599 |

9269 |

Nigerian

Goat |

Native

+ Veg (UK) |

3.1 |

1.7 |

77 |

40 |

55543 |

18 |

Nigerian

Goat |

Veg

(native tanned) |

4.4 |

2.2 |

78 |

60 |

9464 |

3668 |

Indian

Goat |

Chrome

+ Veg |

4.2 |

1.9 |

83 |

56 |

30287 |

120 |

Indian

Goat |

Veg

Chieftain Goat |

3.5 |

1.9 |

83 |

56 |

30087 |

120 |

Indian

Goat |

Archival

- Best Result |

4.8 |

3.0 |

>115 |

84 |

336962 |

49889 |

| Indian

Goat |

Archival

- Average to date |

4.2 |

2.8 |

114 |

83 |

165000 |

14000 |

European

Goat |

Vellum |

5.3 |

3.4 |

63 |

49 |

20786 |

7396 |

European

Goat |

Alum Goat |

3.9 |

4.0 |

80 |

64 |

12883 |

2469 |

Summary

Leather

Type |

Tannage |

Bookbibding

Tests |

Physical

Tests |

Aged

Tests |

Indian

Goat |

Veg

+ Chrome re-tan |

Fail |

Fail |

Pass |

Indian

Goat |

Full

Chrome Tannage |

Fail |

Fail |

Pass |

Nigerian

Goat |

Native

+ Veg (UK) |

Pass |

Pass |

Fail |

Nigerian

Goat |

Veg

(native tanned) |

Pass |

Pass |

Pass |

Indian

Goat |

Chrome

+ Veg |

Fail |

Fail |

Pass |

Indian

Goat |

Veg

Chieftain Goat |

Pass |

Pass |

Fail |

Indian

Goat |

Archival

- Best Result |

Pass |

Pass |

Pass |

| Indian

Goat |

Archival

- Average to date |

Pass |

Pass |

Pass |

European

Goat |

Vellum |

Pass |

Pass |

Pass |

European

Goat |

Alum Goat |

Pass |

Pass |

Pass |