Volume 14 - Autumn 2002

Period Finishing

by Trevor Lloyd

The following article is the text that accompanied Trevor's lecture at the Society of Bookbinders Residential Standards Training Seminar, Birmingham, June 2002

There are a myriad of books and texts available to the learning and improving finisher. From Dudin, through Minshall, Cowie, Zaensdorf, Cockerell, Johnson and Mitchell, all give excellent, though at times somewhat conflicting advice, the basic principles do though always remain the same; bright gold tooling, being the result of a combination of correct preparation, heat, pressure and dwell time.

Malthus.

Principles of Population 1803 Full diced Russia. 4to

Malthus.

Principles of Population 1803 Full diced Russia. 4to

Having learnt all my finishing as a result of reading everything I could on the subject, and then having to transfer that into practice, I can only offer a few tips that have "worked " for me over the last twenty years!

The first and most important point that comes to mind is that today's binder works in a very dry environment, this can affect finishing greatly. Minshall (if he is indeed the author) notes in his book, The Whole Art of Bookbinding, (the first book in English to be solely devoted to bookbinding, Oswestry 1811) that more books can be finished when it is mild than can be when it is either very hot or very cold. Having lived in several stone houses, not too far from Oswestry, and having an habitual eye on the Hygrometer, I can safely say that in very cold weather and very hot weather the relative humidity in older properties drops. But when it is mild particularly between seasons the RH goes up.

I was made dramatically aware of this when I went to work in one of the Southern States of America, I thought naively that because the place was so humid finishing would be very easy. Outside the RH was 95% however inside the air conditioning reduced it to 20%, consequently it was impossible to retain any moisture in the leather at all. I had to resort to getting a humidifier in to the bindery in order to be able to do any finishing of any appreciable quality at all. I know of other binders in the States who drape a damp towel over the book for ten minutes or so to increase the moisture content of the leather.

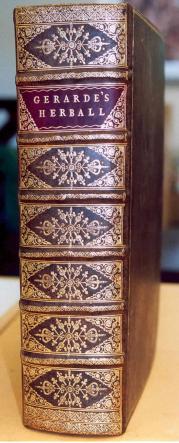

Gerardes

Herbal. 1597 calf reback reproducing spine folio

Gerardes

Herbal. 1597 calf reback reproducing spine folio

Looking at pictures of Roger Payne, his London basement must have been pretty damp. Coupled with working on books that were generally kept in damper conditions than now, leads me to suspect that in general finishers of the past worked on leather with a greater moisture content than we do now.

There are of course great benefits in today's drier environment for the book's longevity, (and the binder's health). I am not suggesting that we should all return to the dark and damp binderies of the past, however I have found that of all the factors affecting finishing, moisture content of the leather (in conjunction with heat) can have the most dramatic outcome on gold adhesion, brightness etc.

To this affect, I always paste wash only the book that I am working on at the time. Paste washing all of a day's books in the morning means that even by the second book the leather has no moisture left in it. As soon as the paste wash feels dry to the touch, usually after only five minutes I apply the first coat of glaire, and once that feels dry, the second coat can be applied. Once this is dry enough to be able to apply a thin coat of Vaseline without the cotton wool dragging I can apply the gold. From first paste wash to tooling can be as short as 20 minutes.

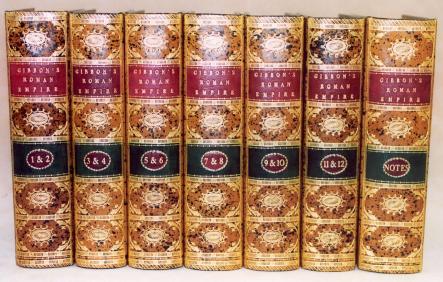

Gibbon's

Roman Empire. 1798. Full marbled calf. 8vo

Gibbon's

Roman Empire. 1798. Full marbled calf. 8vo

A natural sponge dipped in water and squeezed reasonably dry, and then dipped in paste which is weaker than average works well, as it provides both moisture for the leather, and seals the surface of the calf.

I make Glaire up as follows: five parts water to one part Albumen crystals, left to soak over night, then strained, and a few drops of milk added, and a dash of vinegar. This works well straight away, up until it has gone off and you can no longer open the bottle without feeling ill!

Temperature for tooling is now critical as with a greater moisture content to the leather the danger of either frosting the gold (or worse) is increased, so a very slight sizzle is just right.

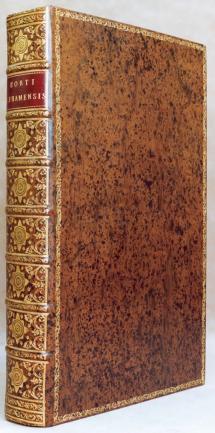

Dilleni

Horti. 1774. Full marbled calf. Folio.

Dilleni

Horti. 1774. Full marbled calf. Folio.

Always polish the face of the tool on a gold cushion with a touch of pumice powder so that it is bright, the gold only mirrors the face of the tool.

I always remove the surplus gold with a gold rubber. Over the years I have recouped literally hundreds and hundreds of pounds worth of gold from the rubber. I then wipe over with a cotton wool pad soaked in refined petrol, which not only removes any remaining gold but the residue of Vaseline as well. A wash over with water lifts the glaire that sits on the surface.

It is always important to feel comfortable when finishing, so use a bench at the right height. It should be well lit, so you can easily see where the tools are going in. It is also important to have a good stance, feet apart, and in a position that allows you to follow the tools over the book, always keeping them at the same distance from your head, so you can visually follow the tool.

Most important of all, tool confidently and don't panic!!!

Happy finishing

Trevor Lloyd - Trevor first encountered book binding in the 1970's whilst as a student in York. He went on to work for Sangorski and Sutcliffe in the early 1980's, and for the last 17 years he has been running his own bindery in the Welsh Marches, specialising in restoration and period binding.