Volume 9 - Spring 2000

The Manufacture of Leather - part 9

by Roger Barlee BSc, M.R.S.C.

In Part 8 of our series "The Manufacture of Leather", Thomas McNeill described the different types of finish used at Hewits. In this article, we will give you a little insight into the different finishing techniques used in the production of bookbinding leathers.

Softening

If

we go back to Part 6, we finished off with the leather leaving the dyehouse

to be dried on sheets of glass or on toggle frames. On removal from the drying

machine, in which we control the temperature and humidity, the skins are flat

and generally quite firm. After an inspection and light trim, the skins are

taken to the finishing department where they are initially softened. The softening

process is carried out in one of three ways, all of which work on the same principle

of flexing the leather around a blunt blade. The action of flexing separates

the fibres from each other. The method used depends on the type of leather and

also the end product being produced.

If

we go back to Part 6, we finished off with the leather leaving the dyehouse

to be dried on sheets of glass or on toggle frames. On removal from the drying

machine, in which we control the temperature and humidity, the skins are flat

and generally quite firm. After an inspection and light trim, the skins are

taken to the finishing department where they are initially softened. The softening

process is carried out in one of three ways, all of which work on the same principle

of flexing the leather around a blunt blade. The action of flexing separates

the fibres from each other. The method used depends on the type of leather and

also the end product being produced.

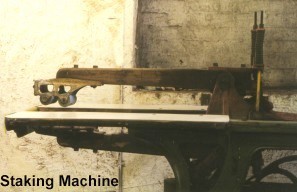

Staking

- Here the skin is held by the operator against a bar, whilst jaws consisting

of rubber rollers and blunt blades grab and pull the skin. The skin is both

flexed and stretched in this process, the most violent method we use to soften

our leather, and is used in the production of our Chieftain Goatskins.

Staking

- Here the skin is held by the operator against a bar, whilst jaws consisting

of rubber rollers and blunt blades grab and pull the skin. The skin is both

flexed and stretched in this process, the most violent method we use to soften

our leather, and is used in the production of our Chieftain Goatskins.

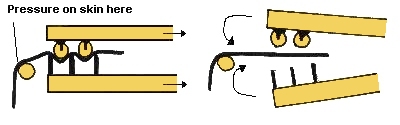

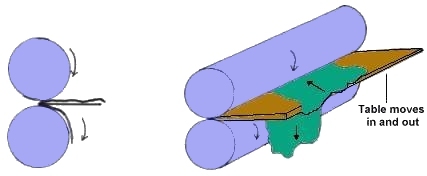

Boarding

- is mainly used on utilitarian leathers (e.g. smooth or embossed goat) that

have been dried on the glass drying machine. A boarding machine consists of

2 rollers with a blunt blade that gets pushed between the rollers. The skin

travels around the blade and is flexed tightly as a result of the nipping action

of the rollers.

Boarding

- is mainly used on utilitarian leathers (e.g. smooth or embossed goat) that

have been dried on the glass drying machine. A boarding machine consists of

2 rollers with a blunt blade that gets pushed between the rollers. The skin

travels around the blade and is flexed tightly as a result of the nipping action

of the rollers.

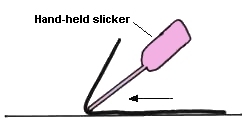

Hand

Slickering - is used on delicate leathers and aniline leathers, where the

harsher action of the staking or boarding machines would damage or mark the

surface of the leather. The leather is wrapped around the hand slicker which

is pushed along the surface of a table.

Hand

Slickering - is used on delicate leathers and aniline leathers, where the

harsher action of the staking or boarding machines would damage or mark the

surface of the leather. The leather is wrapped around the hand slicker which

is pushed along the surface of a table.

Colour Application

Following on from the softening of the leather, the leather is then sprayed with one of the finishes mentioned in part 8. There is an inverse relationship between the amount (and opacity) of finish applied and the quality of the surface of the leather.

The best quality skins, such as our aniline Bookcalf, are sprayed in with just dye and water. Natural grained goatskins (Chieftain and Clansman), where the surface has some minor imperfections from roaming through scrub-lands require some degree of opacity. They are therefore sprayed with an aniline/casein finish. The casein has two uses in that it holds the dyestuffs above the surface of the leather giving opacity, and it also gives a uniform surface for later polishing. Finally there are the leathers that are sprayed in with a fully opaque pigmented finish. Skins in this category can vary quite widely in quality - from smooth leathers (minor blemishes/staining) to heavily embossed leathers (deep scars/insect damage).

The skins are placed on a conveyor and pass through a spray chamber where colour is applied from a spray gun travelling across the skin on an arm. Following the spray chamber, the skins move into a drying chamber, before coming off the conveyor where they are either piled or hung to dry. Depending on the type of finish being applied, skins will receive between two and eight light coats of colour in order to achieve the desired effect.

Post Colouring

Operations

Post Colouring

Operations

After the skins have been sprayed in to the correct colour, with the appropriate type of finish, the processes for completing the finishing operations vary quite markedly.

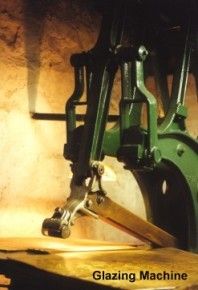

Aniline leathers require no more work, and are now taken to the warehouse. The natural grained goats (Chieftain and Clansman) are burnished using a glazing machine. This machine has a glass chuck that travels over the surface of the skin polishing the tips of the grain and thus creating a two-tone effect. The operation is very similar to that carried out by bookbinders using polishing irons, except that the area covered in one stroke is 10cms wide and 50cms in length. The glass chuck repeats the stroke 2-3 times per second allowing a typical skin to be glazed in about 30 seconds.

Finally the pigmented leathers are generally pressed under heat. In the case of the smooth and glazed leathers, the skins are initially pressed with a "haircell" plate, in order to break up any minor imperfections, before the skins are pressed using a plain plate. Skins that have more major damage are normally embossed using plates that have been engraved with a "perfect" grain. When the acrylic resin finish comes into contact with these plates under heat, the thermoplastic finish re-forms to the shape of the plate, thus helping to cover blemishes. In all cases, the pressing or embossing of the leather compacts the fibres, therefore before these leathers are sent up to the warehouse they are put through the boarding machine again in order to relax the fibre structure.